Fixing Sailboats -Can You Trust the Rigger? New headstay Inside Profurl, Sailboat How To Videos #21

Sailing 7 years ago 8,755 views

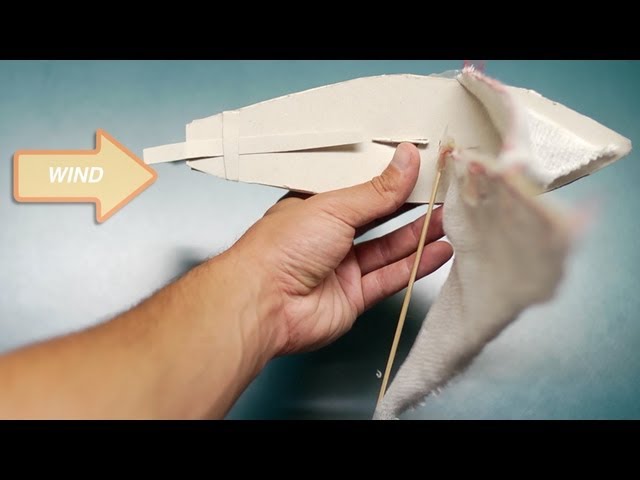

Fixing Sailboats asks “Can you trust the professional rigger to do it right?” Not always! A bluewater sailboat owner has to manage this sailboat project.. Learn how to install a new head stay , inside of a Profurl foil and properly reinstall it, while the mast is still standing. This is one of Patrick Childress’ Sailboat How To Videos, where he shares yer endless sailing tips. Trouble raising and lowering the sail on the Furler? Ripping your sail tape lowering and raising the jib? This video covers what we did to fix the foils from coming loose which was causing this problem. Here are the sailing tips and tricks of Rigging and repairing your Sailboat on the Sailboat How To Videos Channel at http://http://www.youtube.com/PatrickChildress . Sailing video#21 Subscribe to our blog at http://www.WhereIsBrickHouse.com Norseman terminals are not produced anymore, but you can get the aftermarket cones here: https://amzn.to/2EcMsNw Here is the proper Loos Tension Gauge, like the one we used, for a sailboat with 9/32”, 5/16”, or 3/8” rigging wire sizes: https://amzn.to/2QOcX2i The Furler Made for Offshore Cruising Sailboats: http://www.jdoqocy.com/click-8942237-10540053?url=https%3A%2F%2Fwww.westmarine.com%2Fbuy%2Fprofurl--c420-cruising-furler-system-for-38-to-40-boats--8024473&cjsku=8024473 Profurl Furlers http://www.profurl.com/furling-systems-basic-classic-elite.html **As an Amazon Associate I earn from qualifying purchases** #PatrickChildressSailing #WhereisBrickHouse #Valiant40 #FixingSailboats

![[NEW] FUNNY VIDEOS 2016| Top 10 Funny Elevator Pranks| VERY FUNNY must see NOW!!!!!](https://img.youtube.com/vi/rmQs7-OZOWw/sddefault.jpg)

https://images.homedepot-static.com/productImages/6763a5b6-88b0-48c4-a7e9-47fb3aaf1913/svn/tekton-screwdriver-sets-2905-64_1000.jpg

EDIT: Just saw this mentioned further on down in the comments. :)

10. comment for Fixing Sailboats -Can You Trust the Rigger? New headstay Inside Profurl, Sailboat How To Videos #21

I had a very weird connection to this video last night and wanted to share it. I own a 2001 Fountaine Pajot with a profurl reefing drum. It's in a yard in Freeport Bahamas getting some repair work done and we were discussing a problem with the extrusion tubes. My lowest one is loose and it separates about 1/2 inch sometimes. The top set screws are tight and the inter tube is fixed there. It's the lower section set screws that are not somehow holding the coupling in place. Well, the yard, nor the island has a rigging professional to look at this so they were going to fly one in from Fort Lauderdale. I told the guys I didn't think I could afford that right now and would think about it. So I got back to my hotel room, drank a beer, and watched a few YouTube videos. I regularly watch sailing videos so - and this is the weird connection - your video of shooting off the flairs popped up on my screen. I half watched it - it was good but didn't really apply to what I do and kind of zoned it out. That video was followed by this one though and what a crazy coincidence. You go into detail of the set screws and how you put in an extra one to make sure they stay tight. It was exactly what I needed to know and literally 3 hours after needing - without searching!! Thank you for taking the time and effort to make these videos. I do have a few questions and wondered if you wouldn't mind communicating with me via e-mail. You can contact me via the name of my channel + @gmail.com

Big thumbs up!

Thanks for your comment.

I did no see it but the America’s Cup boat that lost its mast probably had Runners. If the windward runners are not released and new windward runners loaded at the right time during a tack or jibe, you can lose the rig.

So wonderful to see folks “living”. God Bless and Fair Winds to you two.

Being pretty good at working on my home I agree much of the time I will do a better job at some things than a professional will do. Mostly because it's mine and it is not theirs so my heart is in it while they are just earning money. But with many years of experience a professional can do things I don't know how to do. So it's educational to work with them but also make the extra effort on some things they will not. I read someplace that a sailor used lanolin on his prop blade surface and it worked well to keep growth off.

20. comment for Fixing Sailboats -Can You Trust the Rigger? New headstay Inside Profurl, Sailboat How To Videos #21

Some thoughts on rig tension and numbers thereof:

Noted that to have a no-sag forestay, your guy had the wire at over 25%, even pushing 30% of breaking strength according to the Loos gauge. Zoiks! I agree with you, that needs backing off. Under the strains of sailing, the wire will still stretch and 'settle in' over time just fine at 10 or 15%, especially at sea where shock loading will temporarily load up much higher from time to time.

Shock loading is why the 'at rest' figure for wire tension is seemingly so conservative. Think of the extra 80-90% of breaking strength as a safety reserve, insurance for an ocean cruiser who, unlike inshore or coastwise racers/sailors, is a long way away from a dock or a tow if the rig fails.

Imagine a wire at near 1/3 breaking strength *while at rest*, taken out into the ocean while attached to a multi-ton boat which suddenly drops off a wave face... That not uncommon scenario could easily create a shock load which uses up the other 2/3 of the wire's reserve strength, and then you'd have real trouble. This is why I like to "keep a little back", because it always seems that the ocean will find a way to take every bit you have otherwise. ;)

WRT the 'twang' method, or "acoustic tensioning" ;) from what I understand/have experienced, when you tension up just past 'thunk' to twang', you've achieved ~10-15% of breaking strength for the wire - which is about where you want to be for the above reasons. So while twang-tuning may not be scientific, it is still fairly accurate, at least enough and on the safe side of the scale to be a "quick and ready" solution. Obviously much better than doing it by eyeball, like the rigger did.

If I could offer an idea? While still at dock, I'd back the stay off to obvious under-tension, then 'thunk' and tighten it back up until you think it might be right, just into the 'twang' range, and then get out the Loos in order to find out how accurate your ears are. :) That will be educational, and knowing the particular note you need to hear for your wire will also allow you to have the ability to get a rough idea of backstay tension when under sail/at sea, without having to dig the Loos out of storage.

Fair winds, and thanks for the video - I'm a new subscriber! :)

Kurt

sailFar.net